|

Alumnized steel sheet and coil

Alumnized steel sheet and coil

Aluminized Steel Sheet: Al-Si alloy coating on the steel, aluminum content of which is 90%, 10% of the silicon。Meet standard: ASTM A-463 Type T1. | Heat resistance:The Aluminized Steel Sheet heat resistance than galvanized steel, cold-rolled steel sheet superior in about 550 degrees below the use for a long time to be almost no change, still maintain its beautiful sheen, but more than 600-degree heat, as a result Al-proliferation and mutual alloy, the surface from becoming deep-gray color, but the metal layer of high melting point, that is, or more than the melting point of aluminum, it does not melt precipitation. And coating the surface temperature of the iron oxide inhibiting the production of phosphorus, in the intense proliferation of aluminum metal surface so that the amount of iron phosphate can not fully suppress the generation of this time, no rapid depletion of the Oxidation of the phenomenon. On the high-temperature oxidation caused by the increase in weight, and 18-8 stainless steel, cold-rolled steel plate, and so on are compared, and the result is heat-resistant properties of the aluminum plate (500-600 ℃) stainless steel plate with almost the same, and more than cold-rolled steel Excellent board for more than 20 times。 | Heat resistance |

|

|

|

|

|

|

|

| Test condition |

|

|

|

|

|

|

|

| →heating:1.5h →maintain temperature:5h →cooling:17h |

|

|

|

|

|

|

|

| Test method:The visual inspection after two rounds of tests conducted |

|

|

|

|

|

|

|

| Result |

|

|

|

|

|

|

|

|

| 300 ℃ | 350 ℃ | 400 ℃ | 450 ℃ | 500 ℃ | 550 ℃ | 600 ℃ | Aluminized Steel Sheet | ○ | ○ | ○ | ○ | ○ | ○ - △ | X | Galvanized Steel Sheet | ○ | ○ | △ | △ - X | X | X | X | Hot-dipsheetgalvanizing | △ | △ - X | X | X | X | X | X |

○: No change △: Gloss drop X : Darke |

|

|

|

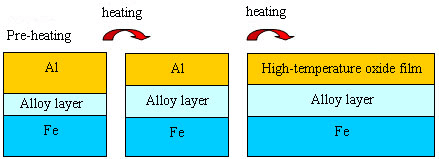

| Mechanism of heat-resistant galvanized steel |

|

|

|

|

Heat-reflective properties:Aluminized Steel Sheet surface, the process is not only beautiful, and there are good reflection of performance, the temperature below 500 degrees, with about 80% of the optical reflectivity; under infrared reflectance was 95% | Thermal Reflectivity |

|

|

|

|

|

|

|

|

| Aluminized Steel Sheet | Hot-dipsheetgalvanizing | 100 ℃× 24h | 80 | 80 | 45 0 ℃× 24h | 80 | 15 |

Corrosion resistance:Aluminum ions in the series, the more Mn, Mo, Cr, W, Cd, Fe, Zn become more resistive. However, since the aluminum oxide film itself has a good stability, so the corrosion resistance of the surface, in addition to some environmental conditions, than a lot of quality galvanized steel sheet. In the atmosphere, as the aluminum plate surface oxides, and the stability of the oxide itself, so there is no direct exposure to aluminum layer on the surface color or appearance, but pinhole or small cross-section of the exposed part of the iron will rust. | Weldability:Compared with the cold-rolled steel sheet, in the welding conditions are different. As the aluminum metal relatively soft, so easy, and as a result of high electrical conductivity, it is part of the welding heat than cold-rolled steel sheet excellent. In addition, the galvanized coating than the melting point of steel, not easily flow into small dissolved and therefore do not have to use galvanized steel sheet as great as the current. | Processing of:Aluminized Steel Sheet between the coating and the substrate, due to the existence of iron alloy, generally considered to be more than cold-rolled steel, galvanized steel plate processing, such as poor. However, on the aluminum plate processing of a variety of features, such as the following method to be able to deal with other steel plate was almost the same as the result of processing. | Performance Coatings:In the aluminum coating on the plate when, in order for the adhesion of stability, to be carried out chemical dealt with the first generation of envelope. The appearance of the surface of aluminum plate is "clean gas" made of molten coating technology, with the last roll coating method of processing as compared with steel plating, as a result of non-embossed, it has a long-lasting gloss, better resistance Erosion and wind resistance. | Green performance:The Aluminized Steel Sheet aluminum layer is made of aluminum, silicon and iron components. By the Government of Japan under the authority of a number of organizations testing confirmed that the chemical is not passive aluminum plate with the Food Sanitation Law, harmless to human health can be directly applied to food processing. The aluminum is also scrap steel can be recycled. |

|

|

|

|

|

|

|

|

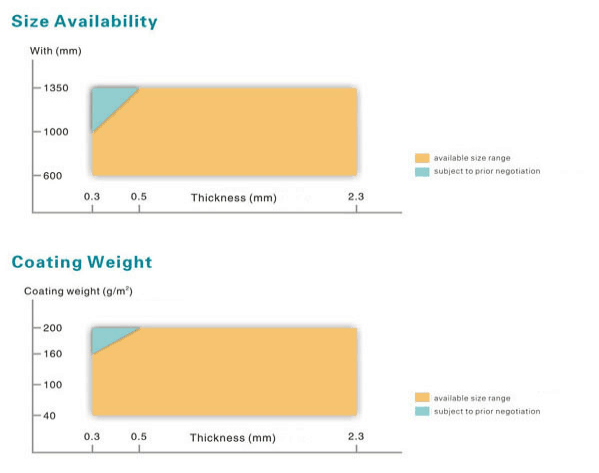

| Product Specification |

|

|

|

|

|

|

|

| Grade and Symbol |

|

|

|

|

|

|

|

|

Class | JIS G 3314 | ASTM A 463 | ASTM A 463-96a | EN 10154 | Commerial Quality | CQ | SA1C | CQ | CS TYPE A | DX51D |

|

|

| (Type 1) | CS TYPE B | DX52D |

|

|

|

| CS TYPE C |

| Drawing Quality | DQ1 | SA1A | ADQ | —— | DX53D |

| DQ2 | SA1D | DQ | FS | DX54D | (Type 1) |

|

|

| DDS | DX55D |

| DQ3 | SA1E | DQSK | —— | —— |

| EDDQ | —— | —— | EDDS | —— | Structural Quality | Grade A | —— | SQ-A | Grade 230 | —— |

| Grade B | —— | SQ-B | Grade 255 | S250GD | (Type 1) |

|

| S280GD |

| Grade C | —— | SQ-C | Grade 275 | S320GD |

| Grade D | —— | SQ-D | Grade 340 Class 1 | S350GD |

|

|

| Grade 340 Class 2 |

| Grade F | —— | —— | Grade 340 Class 3 | —— |

| Grade E | —— | —— | Grade 550 | —— |

Merchanical Properties | Specification |

Class | Tension Strength | Yield point ( kg/m ㎡) | Elongation ( % ) |

| Thickness ( mm ) | Thickness ( mm ) | ( kg/m ㎡) | t ≤ 0.5 | 0.5 < t | t ≤ 0.5 | 0. 5 < t≤ 1.2 | 1. 2 < t | Commerial Quality | CQ | SA1C ,CQ | 28min | 21min | —— | —— | —— | —— |

| ( Type 1 ) | Drawing Quality | DQ1 | SA1A ,ADQ | 28min | 26max | 25max | 34min | 36min | 38min |

| DQ2 | SA1D ,DQ | 28min | 24max | 23max | 36min | 38min | 40min | ( Type 1 ) | DQ3 | SA1E ,DQSK | 28min | 21max | 20max | 38min | 40min | 42min |

| EDDQ | SA1S ,EDDQ | 26min | 19max | 18max | 40min | 42min | 44min | Structural Quality | Grade A | SAC31 ,SQ-A | 31min | 21min | 21min | 20min | 20min | 20min |

| Grade B | SAC35 ,SQ-B | 35min | 25min | 25min | 20min | 20min | 20min | ( Type 1 ) | Grade C | SAC41 ,SQ-C | 41min | 39min | 30min | 18min | 18min | 18min |

| Grade D | SAC45 ,SQ-D | 45min | 37min | 37min | 18min | 18min | 18min |

|

|

|

|

|

|

|

|

|

Scope of Manufacturing Field |

|

|

|

|

|

|

|

|

|

Chromated | Oiled | Chromated & Oiled | No Treatment | Chrome Free Treament | ○ | ○ | ○ | ○ | ○ |

Chromating: |

|

|

|

|

|

|

| →Average:11.5㎎/㎡ →Range:6.8-18.9㎎/㎡ |

|

|

|

|

|

|

| Oiling |

|

|

|

|

|

|

| → Slightly: 500-800㎎ /㎡( one side) |

|

|

|

|

|

|

| → Normal: 1000-1400㎎ /㎡( one side) |

|

|

|

|

|

|

| → Heavy: 1400-2000㎎ /㎡( one side) |

|

|

|

|

|

|

| Applications |

|

|

|

|

|

|

| ① vehicle: muffler, exhaust pipe, fuel tank, etc.; |

|

|

|

|

|

|

| ② the combustion chamber, heat exchanger, desiccant, air conditioning, etc.; |

|

|

|

|

|

|

| ③ appliances: boilers, gas stove, bake me, rice cookers, chimneys, grills, heaters, tubes, |

|

|

|

|

|

|

| microwave ovens, electric switch, such as babeque drill; |

|

|

|

|

|

|

| ④ the construction industry: decorative material, walls, roofs, etc. |

|

|

|

|

|

|

|

|

|