|

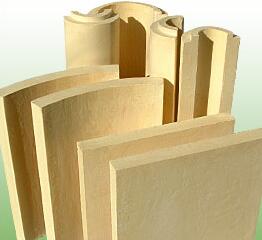

Common: PU (Polyurethane foam)

Polyurethane foam insulation is an ideal kind of organic low temperature heat insulation material. Its thermal conductivity is very little, with light weight and shockproof. It can be made into prefabrications and also can be made cast-in-place. It can be used in oil refining, chemical industry, chemical fertilizer, cold storage, etc. Our materials meet ASTM C591. We can supply Polyurethane foam board, pipe section, or them with kraft aluminium multilayer complex, or with others. No CFC's or HFC C141-b shall be used in the production of PU foam materials.

| Data Sheet: |

| Properties | Physical Index | Physical Index | Item | Unit | N-Type II | N-Type I | Density | kg/m3 | 35-55 | 100 | Maximum use temperature | ℃ | -190~149 | -190~149 | Thermal conductivity | W/mK | 0.02 | 0.03 | Water absorption 24h | (V/V)% | ≤3 | ≤3 | Non-flammable rigid polyurethane foam |

| ok | ok | Thermal conductivity : as per ASTM C 591, Grade 2, Type IV |

| OK |

| Flame resistance : |

| self-extinguishing | self-extinguishing | Thermal resistance of 1.0-in. (25-mm) thickness, min, at mean temperature: |

|

|

| 4℃ |

| k.m2/W | 1.1 | 1.1 | 24℃ |

|

| 1 | 1 | 43℃ |

|

| 0.9 | 0.9 | Dimensional stability |

|

|

| 70±2, 97±3%, relative humidity | % linear change,max | 4 | 4 | -40±3, ambient relative humidity | 1 | 1 | 100±2, ambient relative humidity | 2 | 2 | Closed cell content, min | % | 92.00 | 92.00 | Compressive resistance at yield or 10% deformation, whichever ovvurs first, min | kPa | 256.00 | 428 | Flame spread rate | < | 25.00 | 25.00 | Chloride ion content | ppm | ≤ 10 ppm | ≤ 10 ppm | Standard size and packaging |

| Class | Items | Sizes | Sizes | Board (Slab) | Length (mm) | 1000~300 | 800 | Width (mm) | 1000~300 | 500 | Thickness (mm) | ≤180 | ≤180 | Pipe cover | Length (mm) | 1000~500 |

| Inside diameter (mm) | 16~3560 |

| Thickness (mm) | ≤180 |

| Standard packaging | Polythene bags or Cardboard cartons |

|

Customized:

POLYURETHANE FOAM (PUR) | Polyurethane foam insulation is an ideal kind of organic low temperature heat insulation material. Its thermal conductivity is very little, with light weight and shockproof. It can be made into prefabrications and also can be made cast-in-place. It can be used in oil refining, chemical industry, chemical fertilizer, cold storage, etc. Our materials meet ASTM C591. We can supply Polyurethane foam board, pipe section, or them with kraft aluminium multilayer complex, or with others. No CFC's or HFC C141-b shall be used in the production of PUR foam materials. |

|

|

|

|

| Data Sheet: |

|

Properties | Physical Index | Physical Index | Item | Unit | Type-45K | Type-55K | Density | kg/m3 | ≥45 | ≥55 | Maximum use temperature | ℃ | -190~110 | -190~110 | Thermal conductivity W/mK | 60 | 0.0250 | 0.0246 | (ASTM C 177) | 40 | 0.0230 | 0.0225 |

|

| 20 | 0.0209 | 0.0207 |

|

| 0 | 0.0190 | 0.0189 |

|

| -20 | 0.0200 | 0.0196 |

|

| -40 | 0.0218 | 0.0217 |

|

| -60 | 0.0213 | 0.0210 |

|

| -80 | 0.0205 | 0.0201 |

|

| -100 | 0.0196 | 0.0193 |

|

| -120 | 0.0189 | 0.0176 |

|

| -160 | 0.0156 | 0.0143 | Thermal resistance of 1.0-in. (25-mm) thickness, min, at mean temperature: |

|

|

| 4℃ |

| k.m2/W | 1.1 | 1.1 | 24℃ |

|

| 1 | 1 | 43℃ |

|

| 0.9 | 0.9 | Dimensional stability |

|

|

| 70±2, 97±3%, relative humidity | % linear change,max | 4 | 4 | -40±3, ambient relative humidity | 1 | 1 | 100±2, ambient relative humidity | 2 | 2 | Closed cell content, min. (ASTM D 6226) | % | 90.00 | 93.00 | Compressive resistance at yield or 10% deformation, whichever ovvurs first, min | kPa | 256.00 | 273 | Flame spread rate (ASTM E 84) | < | 25.00 | 23.00 | Water absorption, max. (ASTM C 534) | % | 3 | 2.5 |

|

|